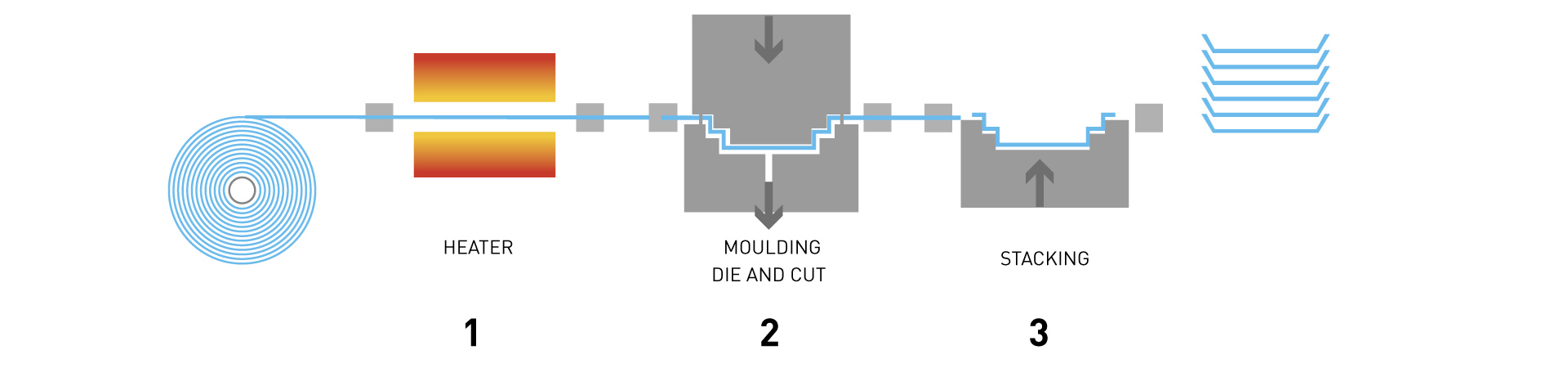

Production Process

Main Features

● InokodzeraPP, APET, PVC, PLA, BOPS, PSpepa repurasitiki.

● Kudyisa, kuumba, kucheka, kusungirirwa kunotungamirirwa ne servo motor.

● Kudyisa, kuumba, mu-mould kucheka uye stacking processing inokwana kugadzirwa otomatiki.

● Mold ine kukurumidza kuchinja mudziyo, nyore kugadzirisa.

● Kugadzira ne7bar air pressure uye vacuum.

● Double selectable stacking systems.

Tsanangudzo

| Model | LQ-TM-3021 | |

| Max Kugadzira Nzvimbo | 760*540mm | |

| Max Kuumba Kudzika/Kureba | Manipulator: 100mm Kudzika pasi stacking: 120mm | |

| Sheet Ukobvu Range | 0.2-1.5mm | |

| Production Speed | 600-1500 kutenderera / awa | |

| Clamping force | 100Ton | |

| Kupisa Simba | 114KW | |

| Motor Power | 33KW | |

| Air Pressure | 0.7Mpa | |

| Kushandiswa Kwemhepo | 3000 litre/min | |

| Kushandisa Mvura | 70 litre/min | |

| Magetsi | Chikamu chetatu, AC 380±15V, 50HZ | |

| Sheet Roll Dia. | 1000mm | |

| Kurema | 10000Kg | |

| Dimension (mm) | Main Machine | 7550*2122*2410 |

| Feeder | 1500*1420*1450 | |

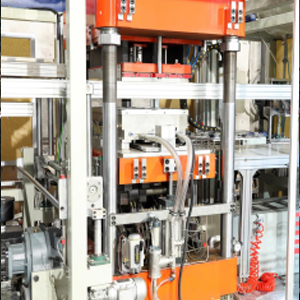

Machine Nhanganyaya

Forming & KuchekaChiteshi

● Panasonic PLC kushanda nyore.

● Kugadzira Koramu: 4 PCS.

● Kutambanudza ne servo motor Yaskawa Japan.

● Kudyiswa mashizha ne servo motor Yaskawa Japan.

Kupisa Ovheni

● (Upper / Lower Ceramic infrared).

● PID mhando ine mwero kudzora.

● Iyo tembiricha yeheater yeyuniti yega yega uye zone yakagadziridzwa paScreen.

● Kubuda otomatiki kana tsaona yemuchina yamira.

Kugadzira Mold

● Rapid mold kuchinja mudziyo.

● Mold automatic memory system.

● Kururama kwepamusoro uye zvigadzirwa zvegoho guru.

● Zvose zvinoumba zvakanaka kana zvakaipa.

● Fast mold kuchinja hurongwa.---------- Sekureva

Kucheka Mold

● Ruler cutter yemhando yakawanda yechigadzirwa.

● Mucheki wevatongi anobva kuJapan.

Stacking Station

● Inmould uye pasi inogona kusarudzwa maererano nemhando yechigadzirwa.

● Kuturika nhamba yakarongwa yechigadzirwa mudura Otomatiki.

● PLC Kudzora.

● Ruoko rwerobhoti runofambiswa ne servo motor Yaskawa Japan.

● Kurongedza otomatiki uye kuverenga kune humwe hutsanana uye kuchengetedza vashandi.